For more than 30 years, Tom-Cin Metals has been providing custom fabrication and build-to-fit designs for bulk storage systems (bins). With a growing customer base, Tom-Cin needed to complement its extensive industry expertise with advanced technology, allowing the company to streamline business processes and optimize the customer experience.

To do this, Tom-Cin needed to invest in:

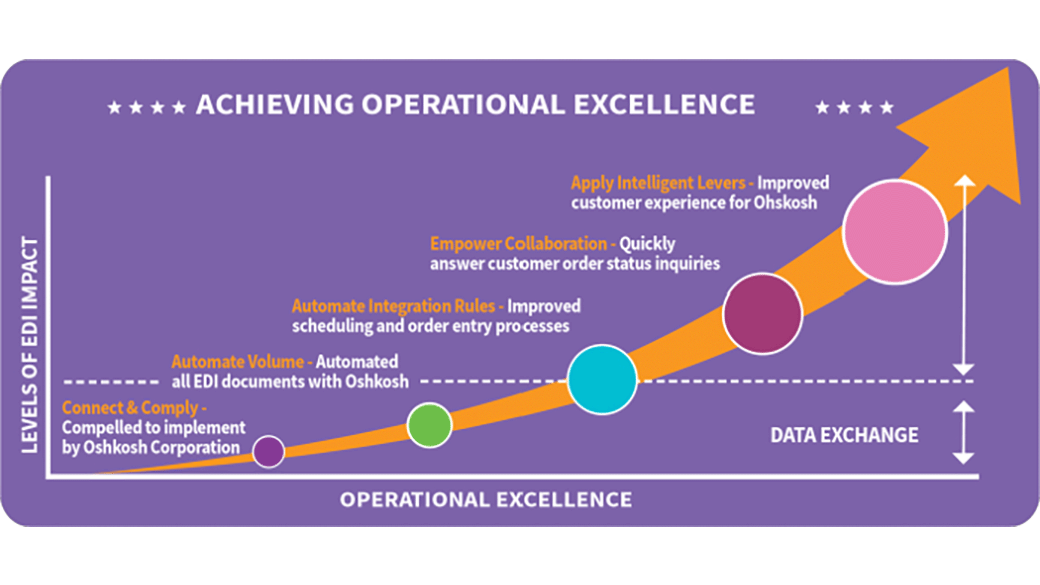

The company struggled between easing into EDI and ERP with a some what advanced solution or ripping off the Band-Aid and implementing the f ull project. Operational efficiency and order accuracy were top priorities for Tom-Cin Metals, who was at the time experiencing major problems with overscheduling, inefficient data entry processes, and inaccurate order handling.

“The old way of doing things was very manual. We had employees scanning, picking and logging material by hand, a very labor intensive experience,” said Joe Chadwick, Quality Manager, Tom-Cin Metals. “As for data collection and inventory, there was a tendency to think that the material was ordered, only to find out later that it wasn’t placed, and we’d have to wait for the material to come in.”

Chadwick adds, “Another common challenge was the inability for customer service or production manager to efficiently manage order entry or respond to an order status call from trading partners and customers. These tasks could easily consume hours, maybe days of lost productivity.

Tom-Cin chose to implement 1 EDI Source’s EDI HQ solution, which seamlessly integrates with the Exact JobBOSS ERP system.

EDI HQ combines EDI translation, data mapping and powerful data management tools to provide enhanced visibility, eliminate the need for manual entry, and reduce transaction errors. And, the ERP system from Exact JobBOSS offered complete visibility, access and job control, and can help customers rest easy knowing the system provides the tools to keep them efficient, productive and profitable.

Total first year savings and on-going year over year savings has been $70,800 and overtime was reduced by 80 percent.

— Joe Chadwick, Quality Manager

Prior to EDI, it would take an order entry clerk eight hours at least once a week to schedule and enter orders. Now, all orders can be entered in just a half of day, which has created a total annual savings of $20,800. Plus they’ve reduced overtime and the amount of missed delivery dates, which has allowed them to achieve higher ratings from trading partners, meaning more work and higher margins.

“Total first year savings and on-going year over year savings has been $70,800, and overtime was reduced by 80 percent,” said Chadwick.

Tom-Cin no longer needed an employee to take orders manually and rekey data. The company’s support staff is now able to quickly answer order questions without chasing down the production manager.

In addition to order entry savings, Tom-Cin was able to move the responsibility of creating pack lists to shipping and receiving personnel, reducing headcount while providing better on-time delivery, more efficient processes, and better utilization of resources.

“By improving scheduling and order entry processes, we are handling orders in half the time and are also enjoying a 75 percent time savings in packaging and shipping processes,” added Chadwick.

Although it can be tough to make changes, Chadwick believes they are all worth it.

“The investment and time we made today will pay off tenfold down the line. In fact, we already have at least one employee who has gone from being extremely frustrated and overworked to focusing her time on other, more rewarding tasks,” said Chadwick.